— Understanding Earthquake-Resistant Design for Maximum Safety —

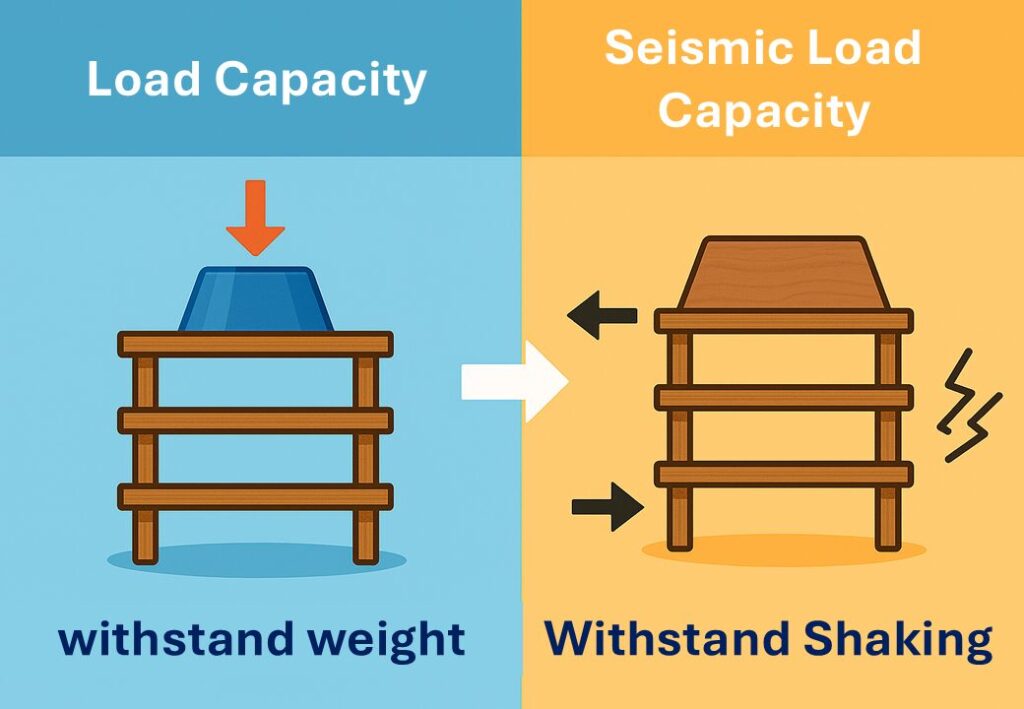

When it comes to earthquake-resistant (anti-seismic) design, knowing the difference between load capacity and seismic load capacity is essential. These two performance indicators determine how well equipment, furniture, or installations can withstand both weight and earthquake-induced shaking. Many people assume “load capacity” covers earthquake safety—but it doesn’t. Let’s break down what each term means and why both matter.

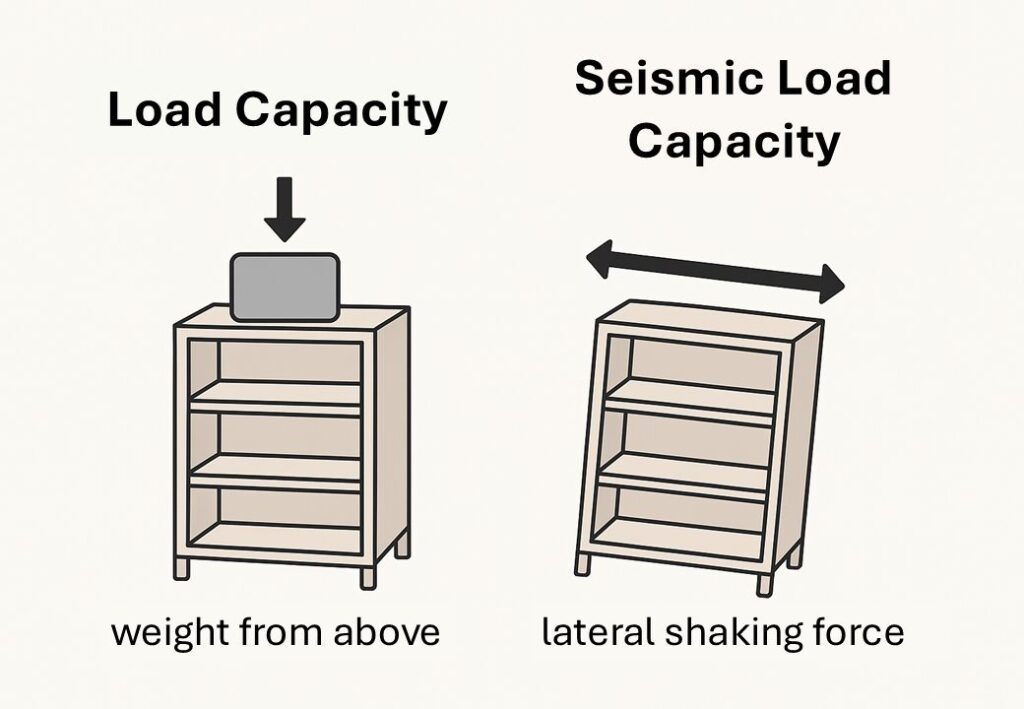

Load capacity, also called static load capacity, refers to the maximum weight a structure can support under normal, non-moving conditions.

For example, a product labeled “Load Capacity: 30 kg” means it can safely hold 30 kilograms of static weight without bending or breaking.

However, this rating only considers gravity and vertical pressure.

It does not consider any horizontal or dynamic forces, such as those caused by vibration, impact, or an earthquake.

In other words, load capacity = weight support during normal use.

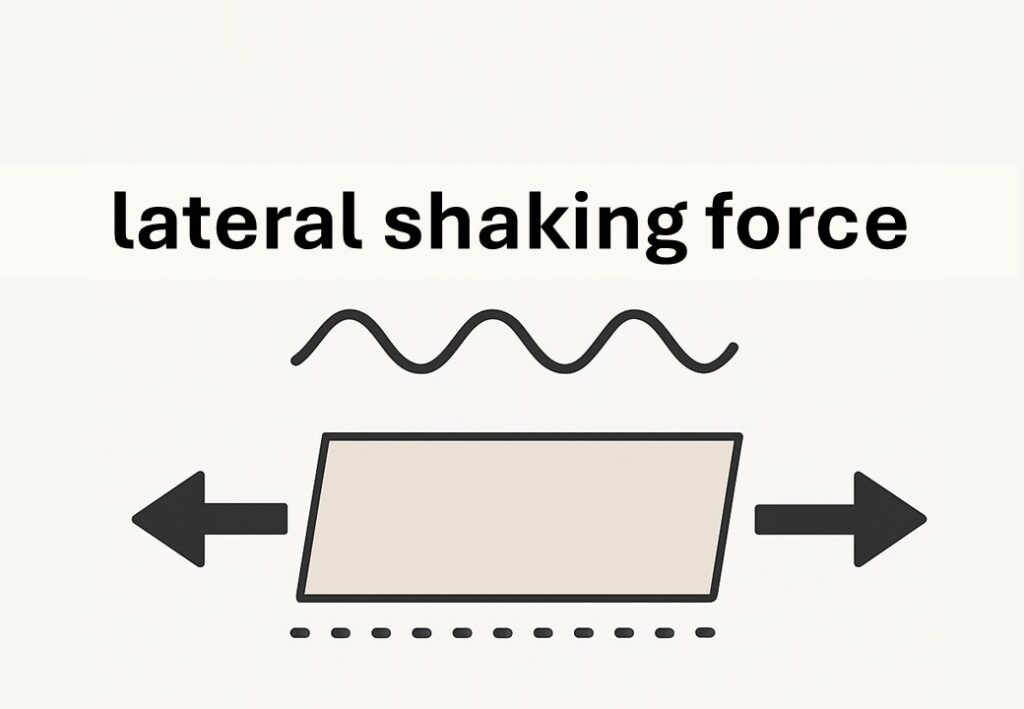

Seismic load capacity measures a product’s ability to withstand dynamic forces generated by earthquakes—including horizontal, vertical, and back-and-forth movements.

During an earthquake, objects are exposed to multi-directional acceleration, often several times greater than their own weight.

This makes seismic load capacity a much stricter performance standard than static load capacity. Products with verified seismic performance are tested on vibration tables or through earthquake simulation tests, ensuring they stay stable and upright even under severe seismic shaking (e.g., equivalent to JMA Seismic Intensity scale 6–7 in Japan).

In short, seismic load capacity = resistance to shaking and impact during earthquakes.

| Feature | Load Capacity | Seismic Load Capacity |

| Type of Force | Static (weight only) | Dynamic (earthquake motion) |

| Direction | Vertical (gravity) | Multi-directional (horizontal, vertical, back-and-forth) |

| Testing Method | Static load test | Seismic or vibration test |

| Example Label | Load Capacity: 30 kg | Seismic Load Capacity: 30kg Passed seismic test, JMA Seismic Intensity scale 7 |

| Meaning of the Terms | Suitable for furniture up to this weight. | It will remain stable during an earthquake even at this weight. |

| Purpose | To support weight | To prevent tipping or falling during earthquakes |

In earthquake-prone regions, such as Japan or the west coast of the U.S., seismic performance can mean the difference between stability and disaster.

Even if a piece of furniture or equipment has a high load capacity, it might topple over easily during an earthquake if it lacks seismic reinforcement.

When choosing earthquake-resistant stands, mounts, or industrial equipment, always check that the product has been seismically tested and designed to handle real-world earthquake forces—not just static loads.

■Proseven Products — Certified for Seismic Load Capacity and Trusted Japanese Quality

All Proseven products are developed, manufactured, and tested entirely in Japan, ensuring the highest level of safety and reliability.

Every product undergoes seismic vibration tests equivalent to JMA Seismic Intensity Scale 7 earthquakes, confirming its resistance against real seismic motion. Unlike ordinary products that display only static load capacity, Proseven labels its performance using seismic load capacity, which reflects the product’s verified ability to withstand actual earthquake forces and acceleration — not just weight.

With proven earthquake-resistant performance and full Japanese production, Proseven continues to lead in reliable seismic technology for both professional and everyday applications.